| Items |

162PDS125-15

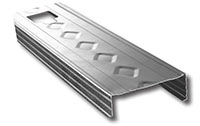

ProSTUD® 0.071 Square Inch (in²) Area Drywall Stud

|

250PDS125-15

ProSTUD® 0.085 Square Inch (in²) Area Drywall Stud

|

362PDS125-15

ProSTUD® 0.102 Square Inch (in²) Area Drywall Stud

|

400PDS125-15

ProSTUD® 0.108 Square Inch (in²) Area Drywall Stud

|

600PDS125-15

ProSTUD® 0.140 Square Inch (in²) Area Drywall Stud

|

|

Description

|

N/A

The ProSTUD® Drywall Framing System with Smart Edge™ Technology can be called many things. Strong. Versatile. Fast. And without a doubt-revolutionary. But one of the biggest benefits to keep in mind is this: ProSTUD® was developed, tested and approved by pros in the field who demanded nothing less than achieving absolute ease of use. Its performance has also been proven by the most extensive laboratory evaluations available. All of which means ProSTUD® comes with complete confidence and no questions about code compliance. With the backing of online, mobile and data-rich BIM resources, there's no better example of a broader vision at work.

|

|

Brands

|

N/A

A-1 Alloys ClarkDietrich® ProSTUD®

|

|

Design Thickness

|

N/A

0.0158 in

|

|

Tensile Strength Fy

|

N/A

50 ksi

|

|

Area

|

N/A

0.071 in²

|

N/A

0.085 in²

|

N/A

0.102 in²

|

N/A

0.108 in²

|

N/A

0.140 in²

|

|

Weight

|

N/A

0.24 lb/ft

|

N/A

0.29 lb/ft

|

N/A

0.35 lb/ft

|

N/A

0.37 lb/ft

|

N/A

0.48 lb/ft

|

|

Gross Section Properties (lx)

|

N/A

0.033 in4

|

N/A

0.088 in4

|

N/A

0.206 in4

|

N/A

0.260 in4

|

N/A

0.683 in4

|

|

Gross Section Properties (Rx)

|

N/A

0.688 in

|

N/A

1.020 in

|

N/A

1.420 in

|

N/A

1.549 in

|

N/A

2.209 in

|

|

Gross Section Properties (ly)

|

N/A

0.015 in4

|

N/A

0.018 in4

|

N/A

0.020 in4

|

N/A

0.021 in4

|

N/A

0.023 in4

|

|

Gross Section Properties (Ry)

|

N/A

0.466 in

|

N/A

0.459 in

|

N/A

0.442 in

|

N/A

0.436 in

|

N/A

0.404 in

|

|

Effective Section Properties at Tensile Strength (Fy) (Ae)

|

N/A

0.033 in²

|

N/A

0.033 in²

|

N/A

0.034 in²

|

N/A

0.034 in²

|

N/A

0.034 in²

|

|

Effective Section Properties at Tensile Strength (Fy) (lx)

|

N/A

0.030 in4

|

N/A

0.080 in4

|

N/A

0.190 in4

|

N/A

0.233 in4

|

N/A

0.537 in4

|

|

Effective Section Properties at Tensile Strength (Fy) (Sx)

|

N/A

0.024 in³

|

N/A

0.044 in³

|

N/A

0.056 in³

|

N/A

0.062 in³

|

N/A

0.105 in³

|

|

Effective Section Properties at Tensile Strength (Fy) (Ma)

|

N/A

719 in·lb

|

N/A

1198 in·lb

|

N/A

1689 in·lb

|

N/A

1870 in·lb

|

N/A

2781 in·lb

|

|

Effective Section Properties at Tensile Strength (Fy) (Vag)

|

N/A

232 lb

|

N/A

147 lb

|

N/A

100 lb

|

N/A

90 lb

|

N/A

60 lb

|

|

Effective Section Properties at Tensile Strength (Fy) (Vanet)

|

N/A

104 lb

|

N/A

141 lb

|

N/A

100 lb

|

N/A

90 lb

|

N/A

60 lb

|

|

Torsional Properties (Jx1000)

|

N/A

0.00589 in4

|

N/A

0.00704 in4

|

N/A

0.00852 in4

|

N/A

0.00901 in4

|

N/A

0.01164 in4

|

|

Torsional Properties (Cw)

|

N/A

0.009 in6

|

N/A

0.023 in6

|

N/A

0.051 in6

|

N/A

0.064 in6

|

N/A

0.161 in6

|

|

Torsional Properties (Xo)

|

N/A

-1.088 in

|

N/A

-0.959 in

|

N/A

-0.837 in

|

N/A

-0.803 in

|

N/A

-0.666 in

|

|

Torsional Properties (Ro)

|

N/A

1.369 in

|

N/A

1.473 in

|

N/A

1.706 in

|

N/A

1.798 in

|

N/A

2.343 in

|

|

Torsional Properties (ß)

|

N/A

0.368 Beta

|

N/A

0.576 Beta

|

N/A

0.760 Beta

|

N/A

0.800 Beta

|

N/A

0.919 Beta

|

|

Length (Lu)

|

N/A

24.8 in

|

N/A

24.5 in

|

N/A

24.3 in

|

N/A

24.2 in

|

N/A

23.6 in

|

|

Shear (#6 Screw 0.138 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

52 lb

|

|

1-Side (#6 Screw 0.138 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

62 lb

|

|

2-Side (#6 Screw 0.138 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

123 lb

|

|

Pullout (#6 Screw 0.138 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

31 lb

|

|

Shear (#8 Screw 0.164 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

56 lb

|

|

1-Side (#8 Screw 0.164 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

62 lb

|

|

2-Side (#8 Screw 0.164 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

123 lb

|

|

Pullout (#8 Screw 0.164 Inch (in) Diameter and 5/16 Inch (in) Head)

|

N/A

37 lb

|

|

Shear (#10 Screw (0.190 Inch (in) Diameter and 0.34 Inch (in) Head)

|

N/A

61 lb

|

|

1-Side (#10 Screw (0.190 Inch (in) Diameter and 0.34 Inch (in) Head)

|

N/A

67 lb

|

|

2-Side (#10 Screw (0.190 Inch (in) Diameter and 0.34 Inch (in) Head)

|

N/A

134 lb

|

|

Pullout (#10 Screw (0.190 Inch (in) Diameter and 0.34 Inch (in) Head)

|

N/A

43 lb

|

|

Notes for Allowable Screw Design Values

|

N/A

- Allowable screw connection capacities are based on Section E4 of the AISI S100-12 Specification.

- When connecting materials of different steel thicknesses or tensile strengths, use the lowest values. Tabulated values assume two sheets of equal thickness are connected.

- Screw shear and tension capacities were developed using published screw manufacturer data and evaluation reports available at the time of publication.

- Screw capacities are based on Allowable Strength Design (ASD) and include a safety factor of 3.0.

- When multiple fasteners are used, screws are assumed to have a center-to-center spacing of at least three times the nominal diameter (d).

- Screws are assumed to have a center-of-screw to edge-of-steel dimension of at least 1-1/2 times the nominal diameter (d) of the screw.

- Tension capacity is based on the lesser of pullout capacity in sheet closest to screw tip, or pullover capacity for sheet closest to screw head (using head diameter).

- Screw capacities are governed by a conservative estimate of screw capacity, not by sheet steel failure.

- For higher screw capacities, especially for screw strength, use specific screws from specific manufacturer. See manufacturer’s data for specific allowable values and

installation instructions.

|

|

Construction Advantages

|

N/A

- High-strength steel combined with low-profile flange stiffening grooves and double offset web planking increases strength and provides greater limiting heights

- Diamond-embossed web creates stiffness, reducing flange fade and screw spinout during drywall installation

- Strong, lightweight stud and track cuts and handles easier than conventional flat steel studs

- Flange grooves provide sight line for drywall alignment and aid in positioning screws at drywall joints to maintain the 3/8" edge requirement

- Web and leg enhancements in ProTRAK® provide straight and rigid legs, making it the best choice for framing walls, headers, soffits, and bulkheads

|

|

Design Advantages

|

N/A

- Designed to meet the additional strength requirements of today's building codes: IBC 2015, AISI (S100), ICC-ES AC86 (2015)

- Smart Edge™ Technology is an enhancement for producing easier-to-handle steel that reduces the risk of cuts and scrapes

- UL Classified and listed in over 50 designs, including U419, V438, and chase wall assemblies

- Exceptional sound performance in over 30 tested sound assemblies

- Can contribute LEED® points in LEED v4 or LEED 2009. EPD and HPD verifications also available.

- National availability

|

|

Addition Information

|

N/A

ProSTUD®, in fact, is just one example of how ClarkDietrich® can reinforce your efforts to design and build more intelligently. Yes, we're known as a manufacturer of extensively tested, code-compliant steel framing products, but we offer so much more. Our products perform as a system. We support a range of efforts for smarter installation and design.

We provide the expertise of a versatile engineering services team. And we do it all on a nationwide scale.

We've put together an incredible array of resources to help you be successful on any project, regardless of size or complexity. Within this catalog you'll discover the multiple advantages ProSTUD® has to offer, as well as detailed information on the product lineup, limiting heights, sound and fire assemblies, and more.

Ultimately, your choice of ProSTUD® doesn't come down to the integrity of the product alone, or even its ease of use. You're also looking to the strength of the company that stands behind it. Count on the expertise, services and full support of ClarkDietrich® today-and far into the future.

|

|

Note

|

N/A

- Calculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard for Cold-Formed Steel Framing-Nonstructural Members.

- Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punch outs.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks.

- For deflection calculations, use the effective moment of inertia.

- Allowable moment includes cold work of forming.

- Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi = 0.

- Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.

|

N/A

- Calculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard for Cold-Formed Steel Framing-Nonstructural Members.

- Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punch outs.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks.

- For deflection calculations, use the effective moment of inertia.

- Allowable moment includes cold work of forming.

- Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi = 0.

- Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.

|

N/A

- Calculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard for Cold-Formed Steel Framing-Nonstructural Members.

- Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punch outs.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks.

- For deflection calculations, use the effective moment of inertia.

- Allowable moment includes cold work of forming.

- Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi = 0.

- Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.

- Web-height to thickness ratio exceeds 200.

|

N/A

- Calculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard for Cold-Formed Steel Framing-Nonstructural Members.

- Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punch outs.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks.

- For deflection calculations, use the effective moment of inertia.

- Allowable moment includes cold work of forming.

- Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi = 0.

- Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.

- Web-height to thickness ratio exceeds 200.

|

N/A

- Calculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard for Cold-Formed Steel Framing-Nonstructural Members.

- Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punch outs.

- Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks.

- For deflection calculations, use the effective moment of inertia.

- Allowable moment includes cold work of forming.

- Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi = 0.

- Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.

- Web-height to thickness ratio exceeds 260.

|