| Items |

HDS3-20-3-5/8

HDS® 0.445 Square Inch (in²) Area Interior and Exterior Framing System

|

HDS3-20-4

HDS® 0.574 Square Inch (in²) Area Interior and Exterior Framing System

|

HDS3-20-6

HDS® 0.715 Square Inch (in²) Area Interior and Exterior Framing System

|

HDS3-20-8

HDS® 0.888 Square Inch (in²) Area Interior and Exterior Framing System

|

HDS3-18-3-5/8

HDS® 1.239 Square Inch (in²) Area Interior and Exterior Framing System

|

|

Description

|

N/A

The HDS® Framing System is a high-performance, cost-effective, multipurpose, heavy-duty framing stud for headers, jambs, posts and built-up tube truss chords and webs. The superior strength and carrying capacity of the HDS® Framing System means higher performance with fewer members. It means eliminating box beam headers, nesting track and stud for posts and jambs, and eliminating multi-member built-up truss chords and webs. It also means improved finish quality by eliminating excessive material and screw head buildup around doors and windows.

|

|

Brands

|

N/A

A-1 Alloys ClarkDietrich® HDS®

|

|

Thickness

|

N/A

20 gauge33 mil

|

N/A

18 gauge43 mil

|

N/A

16 gauge54 mil

|

N/A

14 gauge68 mil

|

N/A

12 gauge97 mil

|

|

Design Thickness

|

N/A

0.0346 in

|

N/A

0.0346 in

|

N/A

0.0346 in

|

N/A

0.0346 in

|

N/A

0.0451 in

|

|

Tensile Strength Fy

|

N/A

33 ksi

|

|

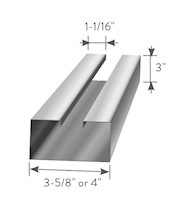

Depth

|

N/A

3-5/8 in

|

N/A

4 in

|

N/A

6 in

|

N/A

8 in

|

N/A

3-5/8 in

|

|

Flange Size

|

N/A

3 in

|

|

Return

|

N/A

1-1/16 in

|

N/A

1-1/16 in

|

N/A

2-1/4 in

|

N/A

2-1/4 in

|

N/A

1-1/16 in

|

|

Double Return

|

N/A

3/4 in

|

|

Minimum Delivered Thickness

|

N/A

0.0329 in

|

N/A

0.0428 in

|

N/A

0.0538 in

|

N/A

0.0677 in

|

N/A

0.0966 in

|

|

Area

|

N/A

0.445 in²

|

N/A

0.574 in²

|

N/A

0.715 in²

|

N/A

0.888 in²

|

N/A

1.239 in²

|

|

Weight

|

N/A

1.52 lb/ft

|

N/A

1.95 lb/ft

|

N/A

2.43 lb/ft

|

N/A

3.02 lb/ft

|

N/A

4.22 lb/ft

|

|

Gross Moment of Inertia About X-Axis (Ix)

|

N/A

0.934 in4

|

N/A

1.198 in4

|

N/A

1.483 in4

|

N/A

1.829 in4

|

N/A

2.520 in4

|

|

Gross Section Modulus About X-Axis (Sx)

|

N/A

0.515 in³

|

N/A

0.661 in³

|

N/A

0.818 in³

|

N/A

1.009 in³

|

N/A

1.390 in³

|

|

Gross Radius of Gyration About X-Axis (Rx)

|

N/A

1.448 in

|

N/A

1.444 in

|

N/A

1.441 in

|

N/A

1.436 in

|

N/A

1.426 in

|

|

Gross Moment of Inertia About Y-Axis (ly)

|

N/A

0.631 in4

|

N/A

0.805 in4

|

N/A

0.990 in4

|

N/A

1.211 in4

|

N/A

1.645 in4

|

|

The Distance from the Web Centerline to the Center of Gravity (xbar)

|

N/A

1.426 in

|

N/A

1.416 in

|

N/A

1.406 in

|

N/A

1.392 in

|

N/A

1.367 in

|

|

Gross Section Modulus About Y-Axis (Sy)

|

N/A

0.405 in³

|

N/A

0.516 in³

|

N/A

0.632 in³

|

N/A

0.770 in³

|

N/A

1.039 in³

|

|

Gross Radius of Gyration About Y-Axis (ry)

|

N/A

1.190 in

|

N/A

1.184 in

|

N/A

1.177 in

|

N/A

1.168 in

|

N/A

1.152 in

|

|

St. Venant Torsion Constant Torsional Properties (Jx1000)

|

N/A

0.178 in4

|

N/A

0.389 in4

|

N/A

0.764 in4

|

N/A

1.503 in4

|

N/A

4.271 in4

|

|

Warping Torsion Constant (Cw)

|

N/A

4.624 in6

|

N/A

5.759 in6

|

N/A

6.894 in6

|

N/A

8.151 in6

|

N/A

10.420 in6

|

|

Distance from Shear Center to the Centroid Along the Principal X-Axis (Xo)

|

N/A

-3.485 in

|

N/A

-3.483 in

|

N/A

-3.480 in

|

N/A

-3.476 in

|

N/A

-3.449 in

|

|

Polar Radius of Gyration About the Centroidal Principal Axis (Ro)

|

N/A

3.957 in

|

N/A

3.952 in

|

N/A

3.946 in

|

N/A

3.938 in

|

N/A

3.906 in

|

|

Distance from Shear Center to the Centroid Along the Principal X-Axis/Polar Radius of Gyration About the Centroidal Principal Axis 1-(Xo/ro)2

|

N/A

0.224 Beta

|

N/A

0.223 Beta

|

N/A

0.222 Beta

|

N/A

0.221 Beta

|

N/A

0.220 Beta

|

|

Maximum Unbraced Length to Attain Mxa (Lu)

|

N/A

103 in

|

N/A

102 in

|

N/A

82 in

|

N/A

82 in

|

N/A

81 in

|

|

Allowable Shear for Bending About X-Axis (Unperforated Vx)

|

N/A

1.03 kips

|

N/A

1.74 kips

|

N/A

3.38 kips

|

N/A

4.37 kips

|

N/A

6.05 kips

|

|

Allowable Shear for Bending About X-Axis (Perforated Vx)

|

N/A

0.54 kips

|

N/A

0.68 kips

|

N/A

1.02 kips

|

N/A

1.00 kips

|

N/A

0.92 kips

|

|

Allowable Shear for Bending About Y-Axis (Vy)

|

N/A

2.05 kips

|

N/A

3.09 kips

|

N/A

5.77 kips

|

N/A

7.06 kips

|

N/A

9.71 kips

|

|

Other Properties (Px)1

|

N/A

0.29 kips

|

N/A

0.46 kips

|

N/A

1.02 kips

|

N/A

1.51 kips

|

N/A

1.97 kips

|

|

Other Properties (Py)2

|

N/A

0.38 kips

|

N/A

0.61 kips

|

N/A

1.38 kips

|

N/A

2.08 kips

|

N/A

4 kips

|

|

Effective Section Modulus About X-Axis (Sxe) Unperforated Bending Properties

|

N/A

0.397 in³

|

N/A

0.565 in³

|

N/A

0.711 in³

|

N/A

0.958 in³

|

N/A

1.390 in³

|

|

Allowable Moment About X-Axis (Mxa) Unperforated Bending Properties

|

N/A

7846 in·lb

|

N/A

11165 in·lb

|

N/A

21290 in·lb

|

N/A

28672 in·lb

|

N/A

45805 in·lb

|

|

Effective Section Modulus About X-Axis (Sye) Unperforated Bending Properties (Web in Ten.)

|

N/A

0.401 in³

|

N/A

0.516 in³

|

N/A

0.632 in³

|

N/A

0.770 in³

|

N/A

1.039 in³

|

|

Allowable Moment About Y-Axis (Mya) Unperforated Bending Properties (Web in Ten.)

|

N/A

7917 in·lb

|

N/A

11703 in·lb

|

N/A

21936 in·lb

|

N/A

27606 in·lb

|

N/A

39444 in·lb

|

|

Effective Section Modulus About X-Axis (Sye) Unperforated Bending Properties (Web in Comp.)

|

N/A

0.294 in³

|

N/A

0.425 in³

|

N/A

0.535 in³

|

N/A

0.733 in³

|

N/A

1.039 in³

|

|

Allowable Moment About Y-Axis (Mya) Unperforated Bending Properties (Web in Comp.)

|

N/A

5814 in·lb

|

N/A

8401 in·lb

|

N/A

16019 in·lb

|

N/A

21944 in·lb

|

N/A

33711 in·lb

|

|

Effective Section Modulus About X-Axis (Sxe) Perforated Bending Properties

|

N/A

0.367 in³

|

N/A

0.540 in³

|

N/A

0.683 in³

|

N/A

0.939 in³

|

N/A

1.375 in³

|

|

Allowable Moment About X-Axis (Mxa) Perforated Bending Properties

|

N/A

7247 in·lb

|

N/A

10674 in·lb

|

N/A

20464 in·lb

|

N/A

28127 in·lb

|

N/A

45285 in·lb

|

|

Effective Section Modulus About X-Axis (Sye) Perforated Bending Properties (Web in Ten.)

|

N/A

0.313 in³

|

N/A

0.400 in³

|

N/A

0.492 in³

|

N/A

0.603 in³

|

N/A

0.820 in³

|

|

Allowable Moment About Y-Axis (Mya) Perforated Bending Properties (Web in Ten.)

|

N/A

6192 in·lb

|

N/A

9080 in·lb

|

N/A

17084 in·lb

|

N/A

21607 in·lb

|

N/A

31127 in·lb

|

|

Effective Section Modulus About X-Axis (Sye) Perforated Bending Properties (Web in Comp.)

|

N/A

0.243 in³

|

N/A

0.342 in³

|

N/A

0.429 in³

|

N/A

0.572 in³

|

N/A

0.820 in³

|

|

Allowable Moment About Y-Axis (Mya) Perforated Bending Properties (Web in Comp.)

|

N/A

4804 in·lb

|

N/A

6753 in·lb

|

N/A

12844 in·lb

|

N/A

17117 in·lb

|

N/A

26602 in·lb

|

|

Effective Moment of Inertia About X-Axis for Deflection Calculations (lxe)

|

N/A

0.851 in4

|

N/A

1.161 in4

|

N/A

1.449 in4

|

N/A

1.829 in4

|

N/A

2.520 in4

|

|

Effective Moment of Inertia About Y-Axis for Deflection Calculations (Web in Ten. (lye))

|

N/A

0.631 in4

|

N/A

0.805 in4

|

N/A

0.990 in4

|

N/A

1.211 in4

|

N/A

1.645 in4

|

|

Effective Moment of Inertia About Y-Axis for Deflection Calculations (Web in Comp. (lye))

|

N/A

0.538 in4

|

N/A

0.741 in4

|

N/A

0.921 in4

|

N/A

1.194 in4

|

N/A

1.645 in4

|

|

Construction Advantages

|

N/A

- Outstanding bending strength in two directions.

- Reduces installation time by 50%.

- Eliminates box beam header assembly.

- Reduces material and labor costs up to 50%.

- HDS® can be screw-attached from either side.

- Eliminates stud-to-track nesting for post, header and jamb studs.

- Openings up to 15' wide.

- Improves drywall finishing around doors and windows. No screw head buildup.

- Superior axial strength.

|

|

Note

|

N/A

Standard material coating is CP60 per ASTM C955; G90 available.

|